- Email orientflex@orientrubber.com

- WhatsApp / Phone+86 180 3186 9514

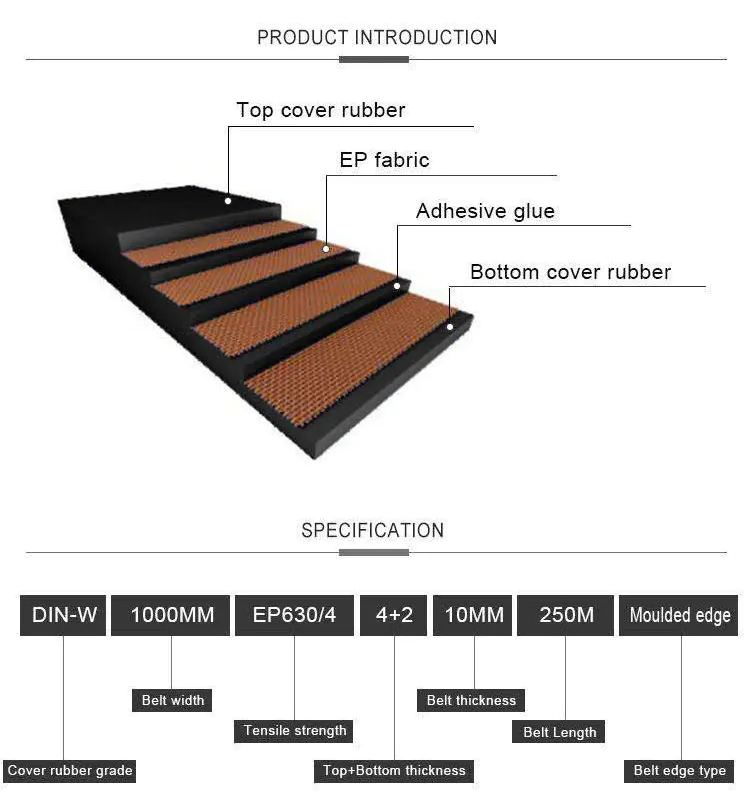

The polyester conveyor belt is also called EP conveying belt. EP fabric plies are sandwiched between rubber skim coats for adhesion and load support. Bottom and top cover compounds are added for maximum protection of the belt carcass.

The EP conveyor belt consisting of two to six EP fabric plies, EP rubber conveyor belt has the same merit as Nylon conveyor belt. Its tensile body is made of warp polyester and weft-knitted canvas. Its performance is characterized by low elongation in the warp direction and excellent groove formation in the weft direction. The wet strength does not decrease, no mildew occurs, the initial modulus of the polyester is high, and a lower safety factor can be taken. It is suitable for conveying materials under medium and long-distance and high load and high-speed conditions.

EP/nylon conveyor belt is suitable for transporting lump, granular, powdery materials of normal temperature, non-corrosion in general conditions. It is widely used in metallurgy, construction materials, wharf, mining industries.

| Type | Standard | Tensile Strength min(MPa) | Ultimate Elongation min(%) | Abrasion max(mm) | Density (g/cm) | Basic Material | Hardness (Sh) | Tenperature (℃) |

|---|---|---|---|---|---|---|---|---|

| GENERALPURPOSE BELTS | ||||||||

| P | MFH-13 | 10 | 300 | 250 | 1.26 | SBR | 60±5 | -45 to +60 |

| N | DIN22102N ISO 10247L BS 10247D |

17 | 1400 | 1150 | 11.13 | SBR | 60±5 | -45 to +60 |

| W | DIN22102W lSO 10247D |

18 | 400 | 90 | 1.12 | NRBR | 60±5 | -60 to +60 |

| V | DIN22102Y | 20 | 400 | 150 | 1.13 | IR/SBR | 60±5 | -45 to +60 |

| X | DIN 22102X lSO 10247H BS 490 M24 |

25 | 450 | 120 | 1.11 | NR | 60±5 | -45 to +60 |

| HEATRESISTANT BELTS | ||||||||

| HEAT | ISO 4195 | 15 | 400 | 150 | 1.13 | SBR | 60±5 | -20 to +60 |

| HIHEAT | MF/H-1" | 10 | 400 | 200 | 1.07 | EPDM | 60±5 | -20 to +60 |

| FIRE RESISTANT BELTS | ||||||||

| K | DIN 22102K ISO 433K |

15 | 400 | 150 | 1.3 | NR/BR | 60±5 | -30 to +60 |

| S | DIN 22102 S ISO 433 S |

15 | 400 | 150 | 1.3 | NR/BR | 60±5 | -30 to +60 |

| VT | DIN22109/4 | 15 | 350 | 200 | 1.29 | MBR/NBR-PVC | 60±5 | -30 to +60 |

| OIL RESISTANT BELTS | ||||||||

| MOR³ | DIN 22102G | 15 | 450 | 200 | 1.12 | MBR/SBR | 60±5 | -30 to +60 |

| PITCH | MFH-6* | 15 | 450 | 200 | 1.11 | MBR/BR/R | 60±5 | -60 to +60 |

| OR | DIN 22102G | 12 | 300 | 200 | 1.25 | MBR | 60±5 | -20 to +60 |

Please enter the information below and we will process your request immediately. If you have an urgent requirement, please call us at +86 180 3186 9514 or orientflex@orientrubber.com.